Cask Care

How to take perfect care of our beer (and keep it on top form)

We want every pint of Taylor’s beer to be as good as it possibly can be.

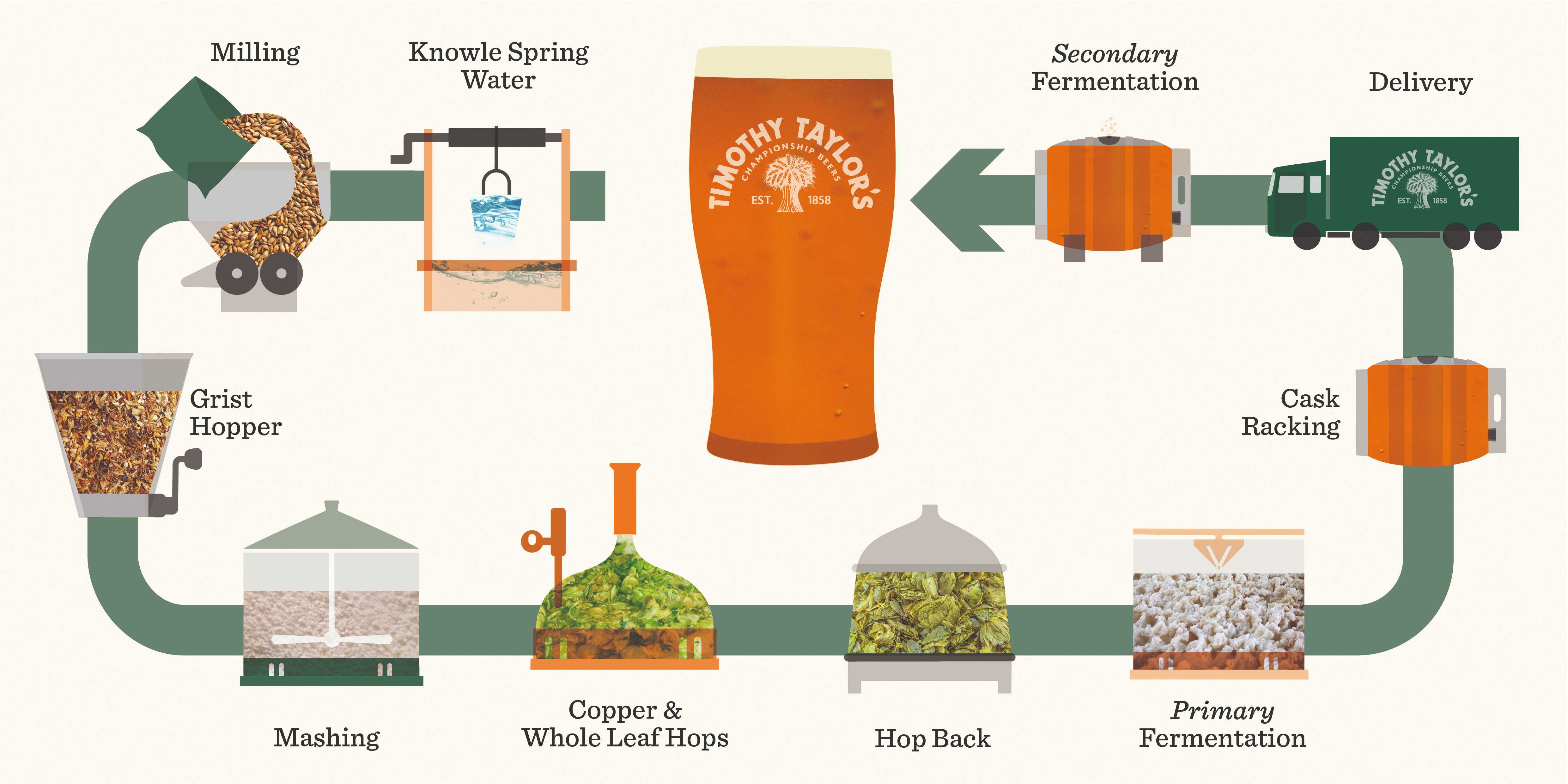

At Timothy Taylor’s we know that one of the most important parts played in the enjoyment of our ales is that of the dedicated publicans and distributors who look after our beer after it has left our brewery.

Without these hard-working individuals and their excellent cellarmanship, drinkers would not be able to enjoy our beers in perfect condition. That’s why we are committed to providing ongoing industry-leading support to every one of our stockists, including technical support, cellar training and expertise to help you serve that perfect pint.

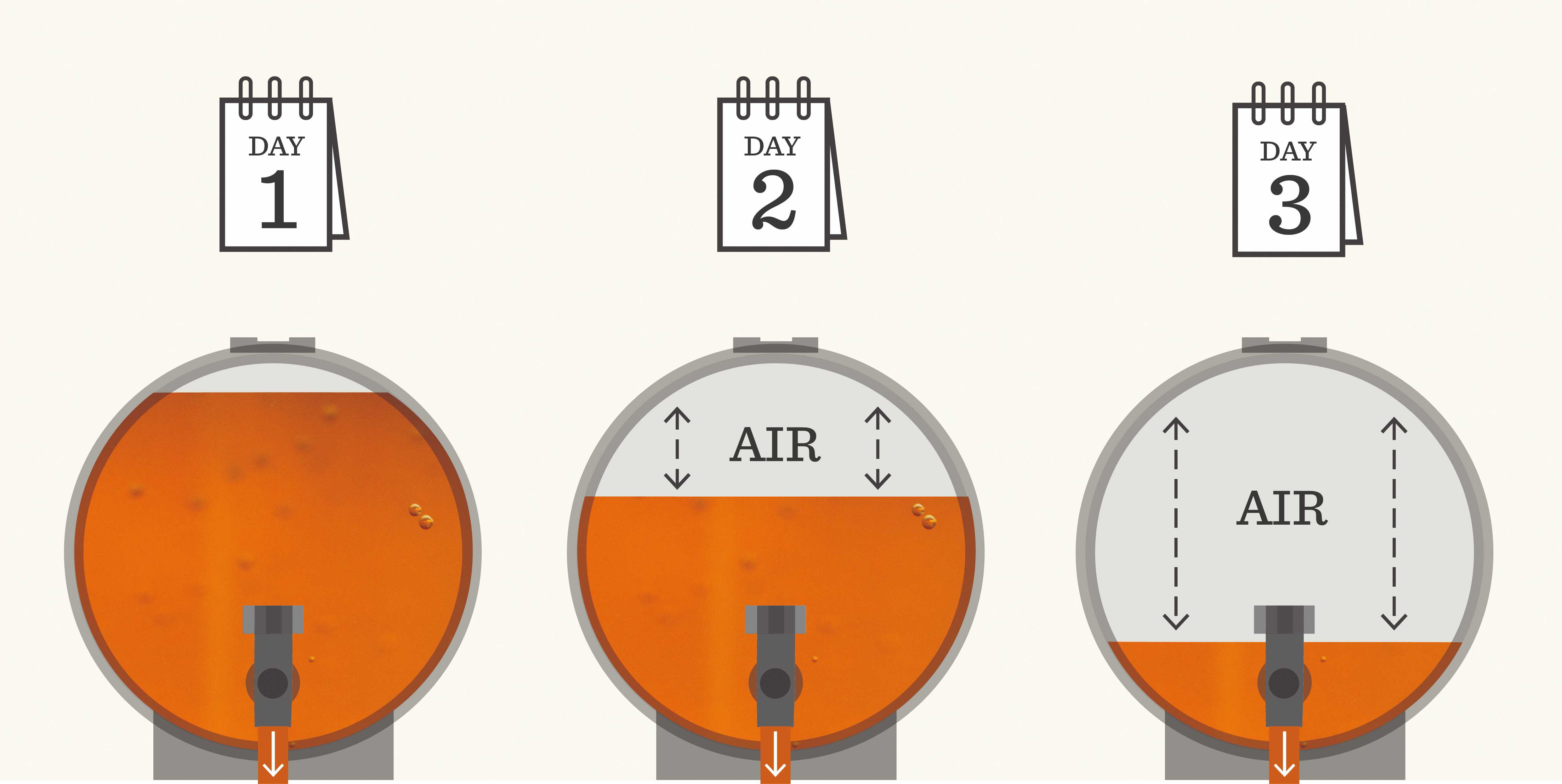

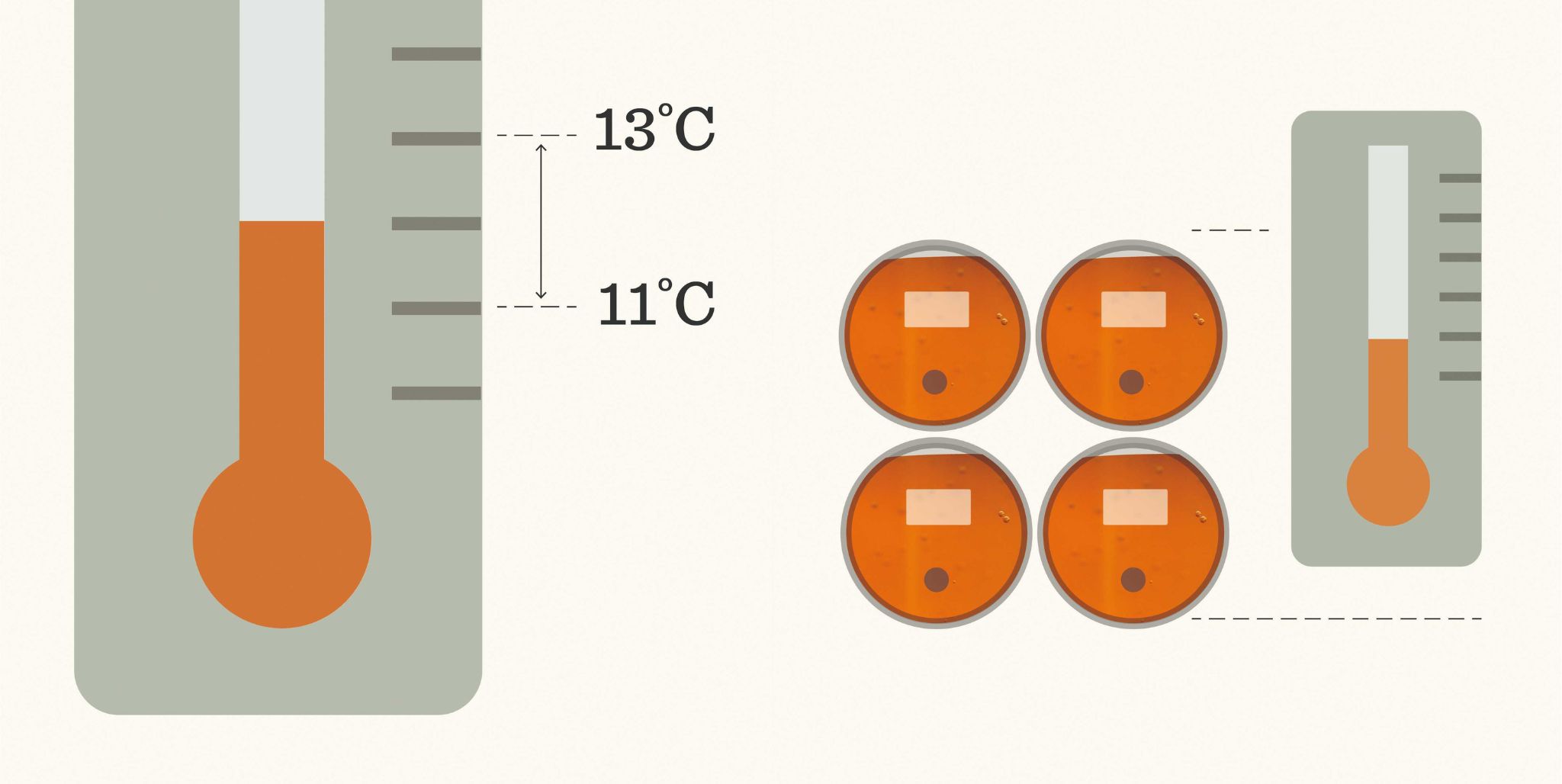

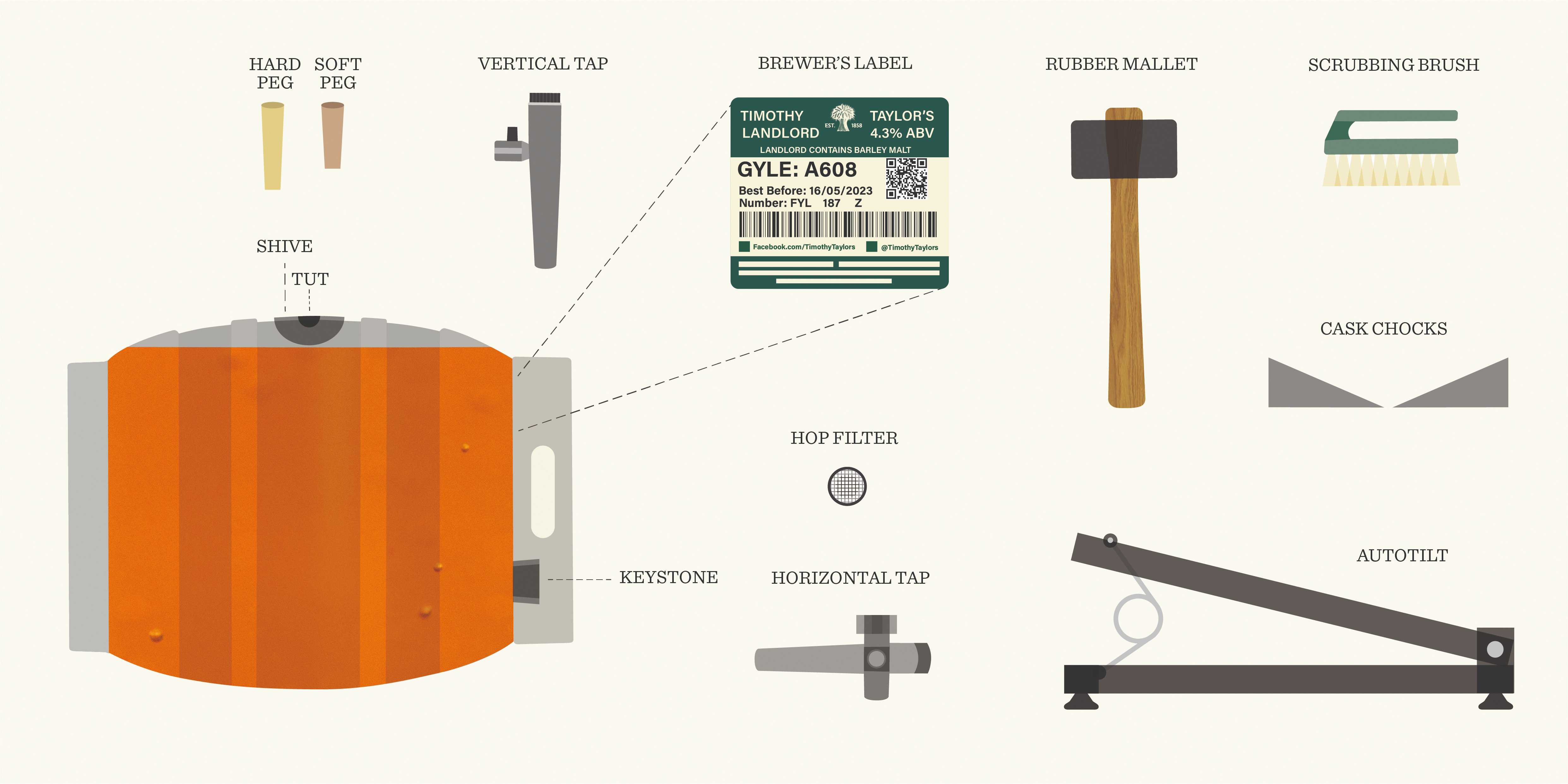

It’s important to remember that cask ale is a live product (unfiltered, unpasteurised and containing yeast) and all casks are born different. Ours require some special care and attention, so we want to show you exactly how we recommend you work with our beers.

We know we can’t be on hand every time so we’ve put together this guide as a handy reminder of the steps to follow to ensure your pub can always deliver the perfect pint of Taylor’s for your customers.