Horizontal – Conditioning

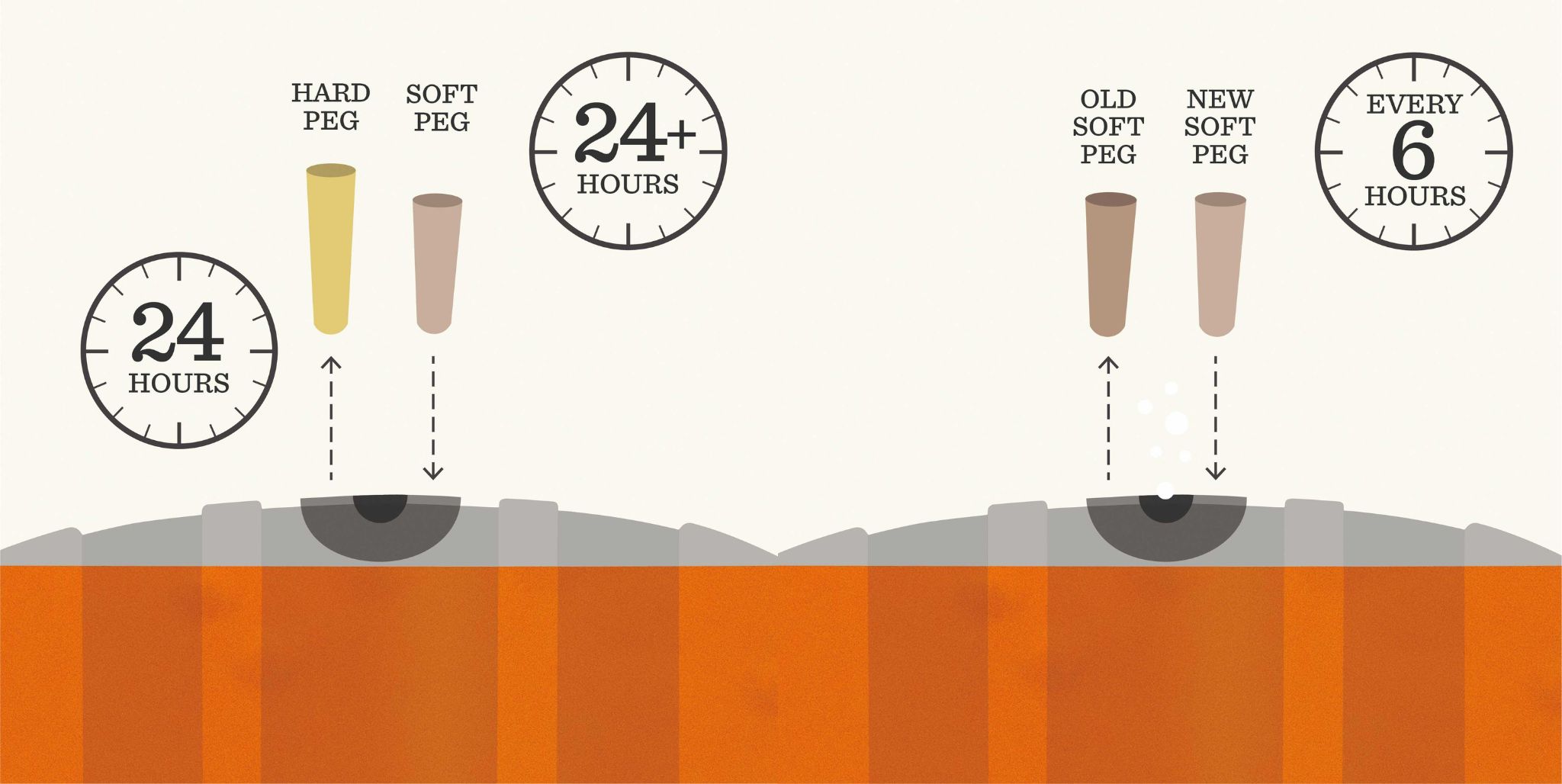

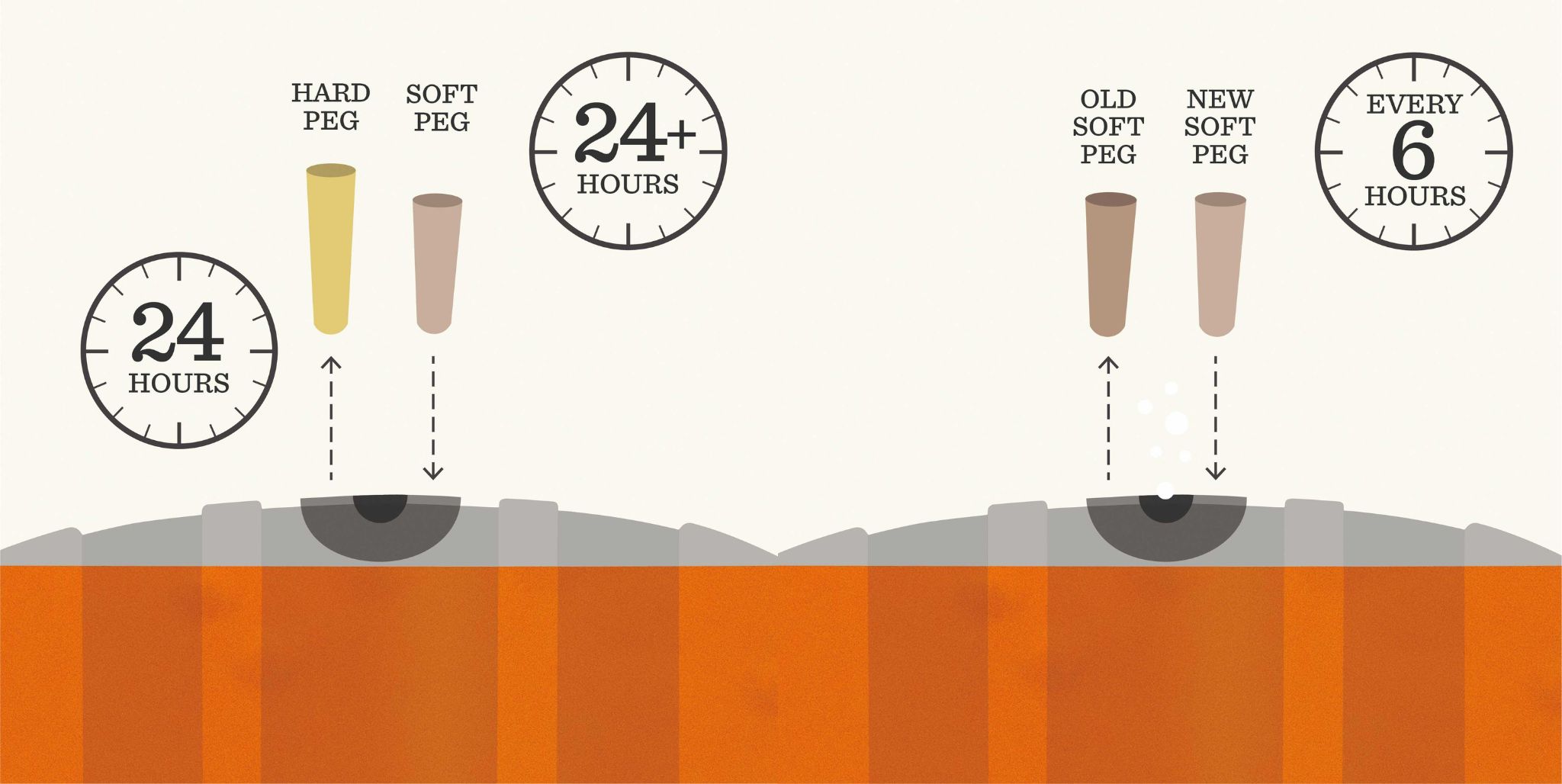

Once you have released that initial gas, remove the hard peg and leave the hole completely empty.

After the initial venting we leave the hole empty for 24 hours, allowing the excess carbon dioxide and froth to be released. Don’t be worried about oxygen getting into the cask as the lively CO2 and froth stops it entering.

Once the emissions stop, clean the shive again and place a soft peg into the hole for at least another 24 hours (H), this allows conditioning to continue.

Check the beer every 6 hours, if you hear the hiss of gas, or froth is still coming out of the cask, replace the soft peg with a new one and leave it for a little longer until this subsides.

When there is no gas or froth released the beer is conditioned. You can then seal it with a hard peg and store ready for when you want to serve it. Now it is fully conditioned.

Ten Day Rule: Once conditioned, beer can be left sealed for up to 10 days before it needs to go on sale (remember it must always be sold within its best before date).